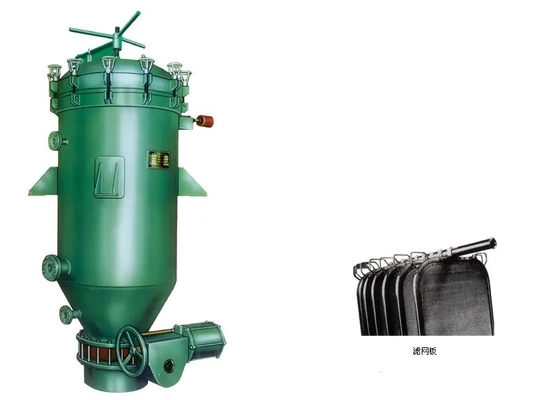

Leaf Filter Clay Filter Decolorizing Filter Automatic Slag Discharger

Leaf filter is a high-efficiency, energy-saving, automatic airtight filtration precision clarification equipment. It is widely used in chemical, petroleum, food, pharmaceutical, metal mineral smelting and other industries. This product has the following characteristics: completely airtight filtration, no leakage, no environmental pollution; automatic pull-out structure of the filter screen plate, easy to observe and clear slag: double-sided filtration, large filter area, large slag capacity; hydraulic control, realize operation automation.

Several elements for the efficient use of vane filters:

1. The filtration speed should be appropriate, which will not cause too much impact on the filter, but also meet the discharge requirements and efficiency requirements.

2. Filtration requirements Generally speaking, the filter element is easy to be damaged, and it is necessary to find a suitable filter.

3. Simple and easy The filtering process should be as simple as possible. If it can be done in one step, it should not be divided into two steps. The more steps, the more complicated it is, the easier it is to cause problems and the more troublesome maintenance will be. filter removal and

Cleaning should be easy to improve efficiency.

The use of leaf filter can be carried out according to the following steps:

First: open the oil inlet valve and the overflow valve, turn on the oil pump, and inject oil into the tank. When the liquid outflow is observed from the overflow pipe sight glass, it means that the raw material liquid has filled the tank.

The second step: close the overflow valve, open the circulation valve, and start the circulation, about 5-10 minutes, when the clear night is observed from the sight glass of the liquid outlet, it means that the filter cake has been formed.

Step 3: Close the circulation valve, open the clearing valve, and start filtration. Generally, the thickness of the filter cake is controlled at 2-3cm. The pressure change can be observed from the pressure gauge on the upper part of the tank. During the filtration process, with the thickening of the filter cake , the pressure rises, generally when the pressure reaches about 4 kg, the oil pump needs to be stopped.

Step 4: During the cake blowing process, stop the oil pump, close the liquid inlet valve, open the inlet valve, and start blowing cake. The pressure is generally maintained at 4-5 kg, and the cake blowing effect is generally 15-30 minutes. In the clear night, the tube sight glass is observed. When there are few half sight mirrors in the clear night, you can stop blowing the cake.

Step 5: In the process of vibrating the slag discharge, open the sewage valve, return the raw liquid in the lower part of the vertebral body to the raw liquid tank, open the exhaust valve, make the pressure return to zero, open the butterfly valve, and vibrate the slag discharge.

| |

Filter cake volume(L) |

Processing power(t/h) |

Workpressure(Mpa) |

Filtering cylinder volume(L) |

I/O Connection |

Discharging outlet |

Cylinder diameter(mm) |

Cylinder height(mm) |

Filter spacing(mm) |

Weight(Kg) |

| Grease |

Resin |

Drinks |

| YWBL-2 |

30 |

0.4-0.6 |

1-1.5 |

1-2 |

0.1-0.4 |

120 |

DN25 |

DN100 |

400*3 |

1280 |

50 |

150 |

| YWBL-4 |

60 |

0.8-1.2 |

2-3 |

2-4 |

250 |

DN40 |

DN125 |

500*3 |

1520 |

50 |

180 |

| YWBL-7 |

105 |

1.4-2 |

3-5 |

4-8 |

420 |

DN40 |

DN150 |

600*3 |

1920 |

50 |

326 |

| YWBL-10 |

150 |

2-3 |

5-8 |

5-10 |

890 |

DN50 |

DN200 |

800*4 |

2120 |

70 |

474 |

| YWBL-12 |

240 |

2.4-3.6 |

6-9 |

6-12 |

1190 |

DN50 |

DN250 |

900*4 |

2220 |

70 |

554 |

| YWBL-15 |

300 |

3-5 |

7-12 |

8-16 |

1580 |

DN50 |

DN250 |

1000*5 |

2370 |

70 |

815 |

| YWBL-20 |

400 |

4-6 |

10-15 |

10-20 |

1770 |

DN65 |

DN250 |

1000*5 |

2670 |

70 |

910 |

| YWBL-25 |

500 |

5-7 |

12-18 |

12-24 |

2200 |

DN65 |

DN300 |

1100*6 |

2740 |

70 |

1024 |

| YWBL-30 |

600 |

6-9 |

14-22 |

15-30 |

2770 |

DN65 |

DN300 |

1200*6 |

2870 |

70 |

1165 |

| YWBL-36 |

720 |

7-10 |

16-24 |

18-36 |

2870 |

DN80 |

DN300 |

1200*6 |

2970 |

70 |

1202 |

| YWBL-40 |

800 |

8-12 |

20-30 |

20-40 |

3500 |

DN80 |

DN350 |

1300*6 |

3070 |

70 |

1342 |

| YWBL-45 |

900 |

9-13 |

22-32 |

22-44 |

3630 |

DN100 |

DN350 |

1300*6 |

3270 |

70 |

1422 |

| YWBL-52 |

1040 |

10-15 |

25-40 |

26-52 |

4380 |

DN100 |

DN350 |

1400*6 |

3370 |

75 |

1900 |

| YWBL-60 |

1200 |

12-18 |

38-42 |

30-60 |

5100 |

DN100 |

DN400 |

1500*8 |

3530 |

75 |

2114 |

| YWBL-70 |

1400 |

14-20 |

35-50 |

35-70 |

6940 |

DN125 |

DN400 |

1600*8 |

4220 |

80 |

2662 |

| YWBL-80 |

1600 |

16-24 |

40-60 |

40-80 |

8300 |

DN125 |

DN400 |

1800*8 |

4220 |

80 |

3882 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!